3D Printing Lancashire | CAD Printing | Print Hub

Firstly we provide a quality 3D printing service ideal for your needs. Please call us here

CAD Printing

Accurate 3d printing of parts with design service . So we supply prototype and functional plastic parts printed to order from your CAD drawings.

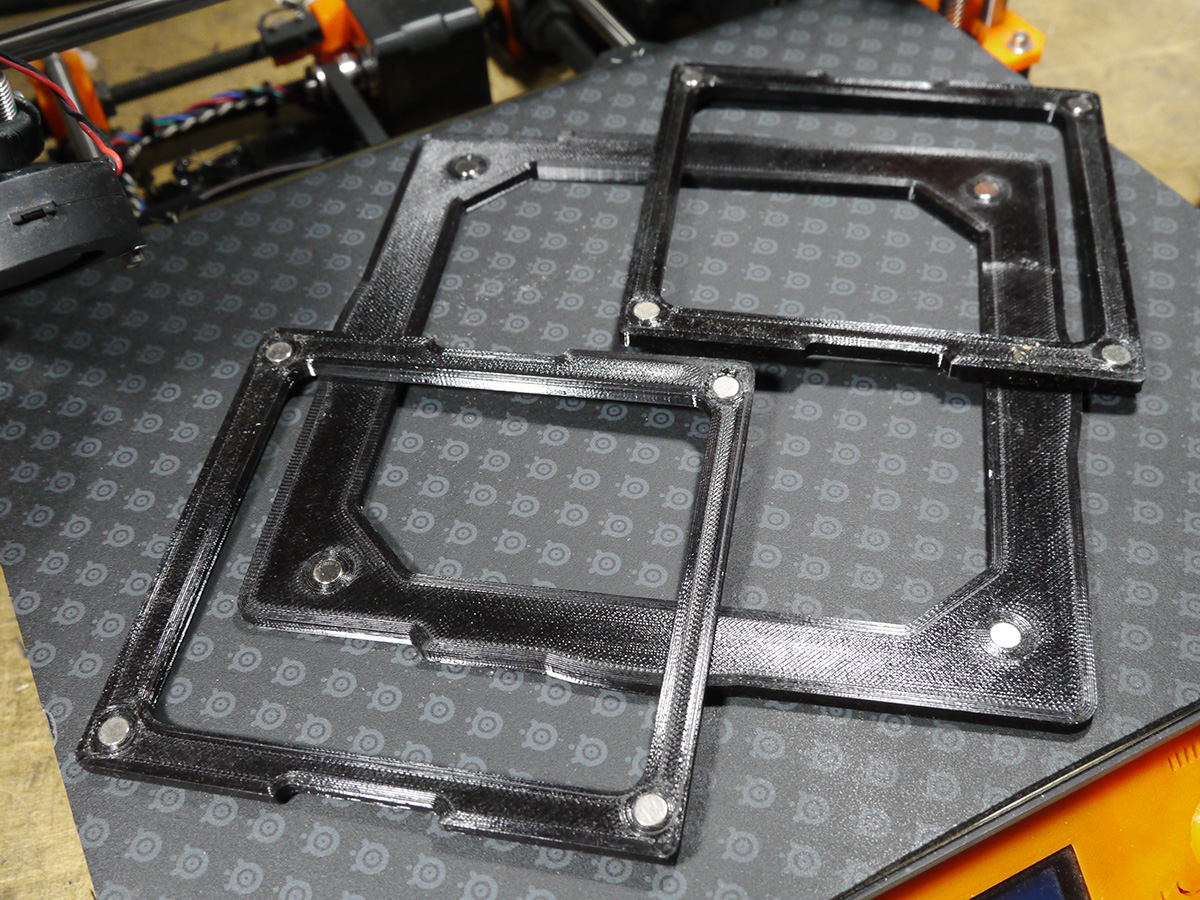

Plates 3D Printed for fitting a quick release bag bellows system to an existing camera. Snuggly fitting holes for strong magnets that hold them in place on the device.

A batch of levers & adapters 3D printed for a mechanism for shutting curtains. Printed on Prusa i3 in resilient PET-G.

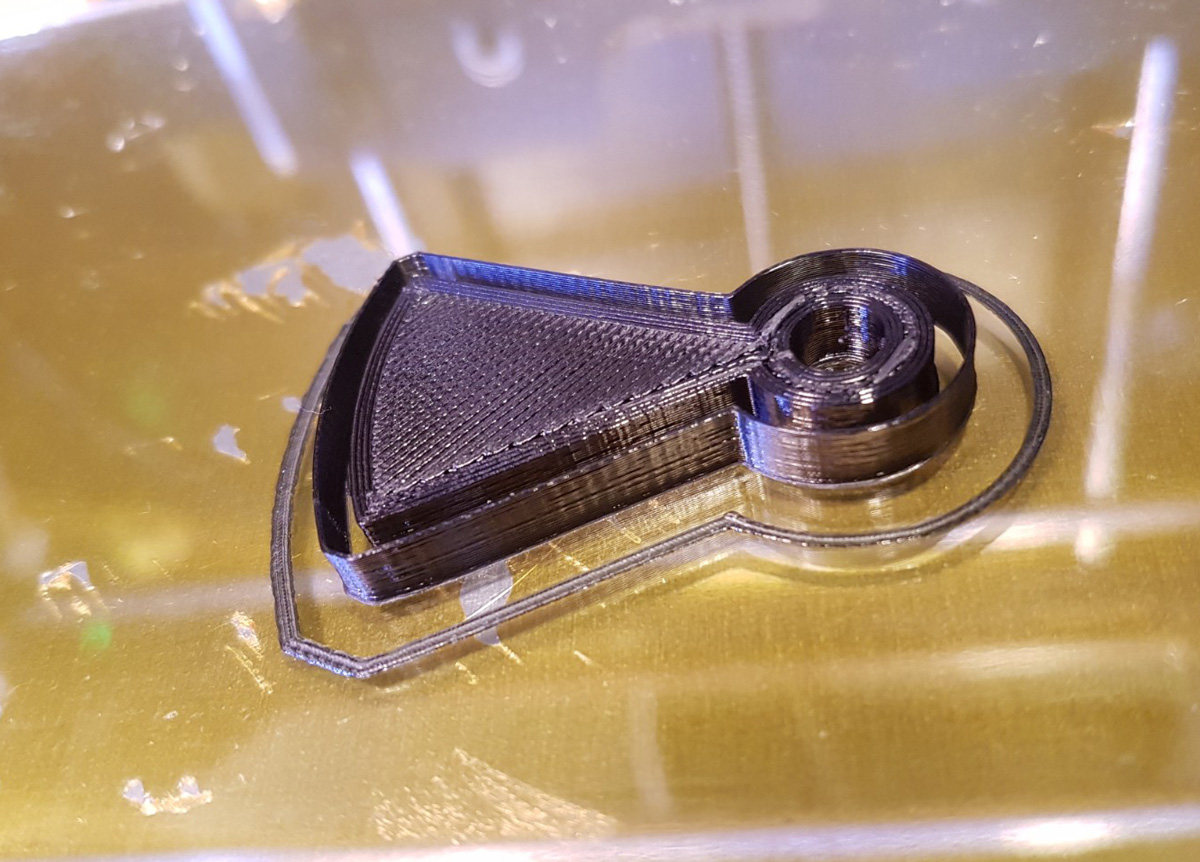

To illustrate these are thumbscrew holders with a captured locknut. So these are 3D printed in a durable material. In detail this is the same plastic as found in spring water bottles.

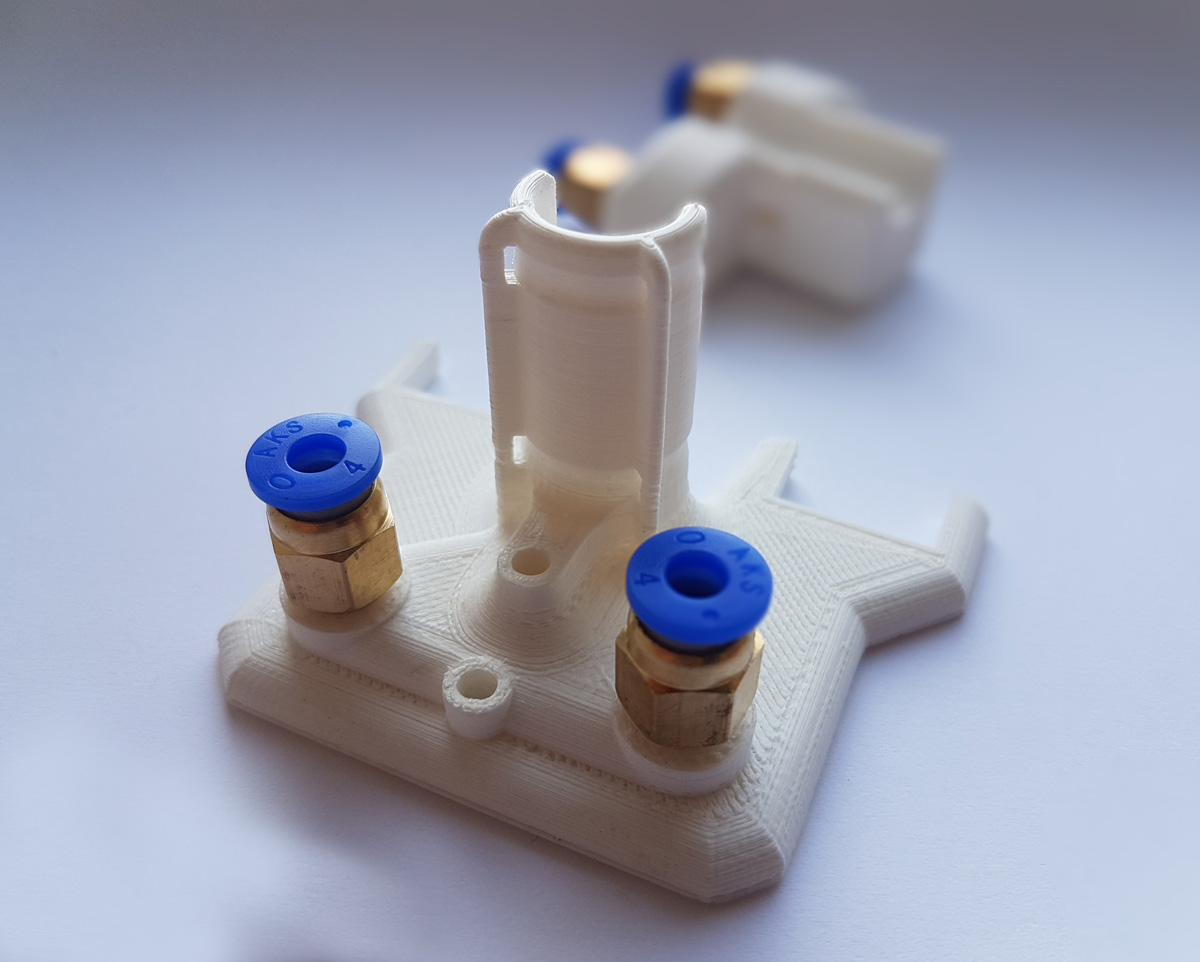

3D prints done with 0.1mm layer height and tapped for screw in brass fittings.

3D printed spool holder 14cm long printed with pearl white filament @ 0.1mm layer with supports for overhangs+threads

3D prints done with 0.1mm layer height and tapped for screw in brass fittings.

3D Printing of strong function accurate parts for mechanisms

Materializing Innovation: Lancashire’s 3D Printing Powerhouse

Lancashire, a region steeped in industrial heritage, is undergoing a modern transformation, driven in part by the burgeoning field of 3D printing. Once synonymous with textiles and mills, Lancashire is now witnessing the emergence of a dynamic ecosystem fueled by additive manufacturing, more commonly known as 3D printing. This article delves into the landscape of 3D printing services in Lancashire, exploring the companies that are pioneering this technology, the industries they serve, the challenges they face, and the exciting future they are building for the region.

The Rise of Additive Manufacturing in Lancashire:

Lancashire’s historical focus on manufacturing provides a fertile ground for the adoption and growth of 3D printing. The skills and expertise developed over generations, coupled with a renewed focus on innovation and technology, have created a favorable environment for businesses specializing in 3D printing services to flourish. The region benefits from a strong network of engineering firms, aerospace companies, and creative industries, all eager to leverage the potential of additive manufacturing.

3D printing offers numerous advantages over traditional manufacturing methods, making it an attractive option for businesses looking to optimize their processes. These advantages include:

- Rapid Prototyping: 3D printing allows for the creation of physical prototypes in a matter of hours or days, significantly reducing development time and costs. This accelerated iteration process allows designers and engineers to test and refine their designs quickly, leading to faster product development cycles.

- Customization and Personalization: Unlike mass production, 3D printing enables the creation of highly customized parts and products tailored to specific needs. This capability is particularly valuable in industries such as healthcare, where patient-specific implants and prosthetics can be manufactured.

- Complex Geometries: 3D printing can produce intricate geometries and complex designs that are impossible or prohibitively expensive to manufacture using traditional methods. This opens up new possibilities for innovation in product design and engineering.

- On-Demand Manufacturing: 3D printing allows for on-demand manufacturing, eliminating the need for large inventories and reducing waste. This is particularly beneficial for businesses that require small batches of parts or products.

- Material Variety: 3D printing utilizes a wide range of materials, including plastics, metals, ceramics, and composites, allowing for the creation of parts with specific functional properties.

Key Players in Lancashire’s 3D Printing Landscape:

Lancashire boasts a diverse range of 3D printing service providers, each with its own specialization and target market. These companies cater to a variety of needs, from rapid prototyping and tooling to end-use part manufacturing and specialized applications. Here are some prominent examples:

- 3D Imaging: Based 25 miles north of Manchester between Clitheroe and Burnley, this company focuses primarily on serving the aerospace and automotive industries. They offer a comprehensive range of 3D printing services. They also provide design optimization services to ensure that parts are designed for optimal 3D printing performance.

- 3D Imaging: Located in the Ribble Valley, this company serves a broader range of industries, including medical, consumer goods, and manufacturing. They specialize in polymer-based 3D printing technologies such as Fused Deposition Modeling (FDM). They offer a wide range of materials, including ABS, PLA, nylon, and TPU, catering to diverse application requirements. Their services encompass prototyping, tooling, and low-volume production of end-use parts. This company is known for its quick turnaround times and competitive pricing, making them an attractive option for businesses looking to rapidly iterate on designs and bring products to market quickly.

- 3D Imaging: This company in Simonstone in the Ribble Valley takes a more specialized approach, focusing on the creative industries. They work closely with artists, designers, and architects to bring their visions to life through 3D printing. They offer advanced services like multi-material printing and full-color 3D printing, allowing for the creation of visually stunning and intricate objects. They are adept at translating complex digital designs into physical forms, enabling the creation of custom sculptures, architectural models, and personalized artwork. They pride themselves on their attention to detail and their ability to push the boundaries of 3D printing technology.

- University of Central Lancashire (UCLan): UCLan plays a crucial role in supporting the growth of 3D printing in Lancashire through its research, development, and training initiatives. The university has invested heavily in state-of-the-art 3D printing equipment and expertise, offering access to cutting-edge technologies for local businesses. UCLan also provides training programs and workshops to equip individuals with the skills and knowledge required to operate and utilize 3D printing technologies effectively. Their research focuses on developing new materials and applications for 3D printing, contributing to the advancement of the technology as a whole.

Applications Across Industries:

The versatility of 3D printing has led to its adoption across a wide range of industries in Lancashire.

- Aerospace: Lancashire has a strong aerospace presence, and 3D printing is revolutionizing the way aircraft components are designed and manufactured. Lightweight and complex parts can be produced using materials like titanium and aluminum alloys, contributing to improved fuel efficiency and performance. 3D printing is also used for creating tooling and jigs required for aircraft assembly.

- Automotive: 3D printing is enabling automotive manufacturers to create customized parts, prototype new designs, and optimize production processes. From creating bespoke interior components to manufacturing specialized tooling, 3D printing is helping to accelerate innovation in the automotive industry.

- Medical: The medical industry is benefiting immensely from 3D printing, particularly in the areas of prosthetics, implants, and surgical planning. Patient-specific implants and prosthetics can be manufactured using biocompatible materials, improving patient outcomes and quality of life. 3D printed models of organs and bones are also used for surgical planning and training.

- Manufacturing: 3D printing is used extensively in manufacturing for creating tooling, jigs, and fixtures. This allows for faster production setup and reduced lead times. It also enables the creation of customized manufacturing aids that improve efficiency and accuracy in production processes.

- Creative Industries: Artists, designers, and architects in Lancashire are harnessing the power of 3D printing to bring their creative visions to life. From creating intricate sculptures and architectural models to manufacturing personalized artwork and jewelry, 3D printing is opening up new possibilities for creative expression.

Challenges and Opportunities:

Despite its immense potential, the 3D printing industry in Lancashire faces several challenges:

- Material Costs: The cost of materials used in 3D printing can be relatively high compared to traditional manufacturing materials. This can be a barrier to entry for some businesses, particularly those involved in large-scale production.

- Skills Gap: There is a growing demand for skilled professionals who can operate and maintain 3D printing equipment, design parts for additive manufacturing, and develop new materials and applications. Addressing this skills gap is crucial for sustaining the growth of the industry.

- Standardization and Certification: The lack of standardized processes and certification programs for 3D printed parts and products can hinder their adoption in some industries, particularly those with stringent quality and safety requirements, like aerospace.

- Scalability: Scaling up 3D printing production to meet the demands of high-volume manufacturing can be challenging. Ensuring consistent quality and repeatability across large production runs is crucial.

However, these challenges also present opportunities for growth and innovation:

- Material Development: Investing in research and development to create new and more affordable 3D printing materials can significantly reduce costs and expand the range of applications.

- Education and Training: Providing comprehensive education and training programs can help to address the skills gap and equip individuals with the expertise required to succeed in the 3D printing industry. Collaboration between universities, colleges, and industry partners is crucial for developing relevant training programs.

- Standardization Efforts: Participating in standardization efforts and developing certification programs can help to build trust in 3D printed parts and products and encourage their adoption across various industries.

- Automation and Optimization: Investing in automation and optimization technologies can help to improve the scalability and efficiency of 3D printing processes, enabling manufacturers to meet the demands of high-volume production.

The Future of 3D Printing in Lancashire:

The future of 3D printing in Lancashire looks bright. The region is well-positioned to capitalize on the growing demand for additive manufacturing solutions, driven by its strong industrial heritage, skilled workforce, and commitment to innovation.

Key trends expected to shape the future of 3D printing in Lancashire include:

- Increased Adoption of Metal 3D Printing: The demand for metal 3D printing is expected to continue to grow, driven by its applications in aerospace, automotive, and medical industries.

- Development of New Materials: The development of new and more advanced 3D printing materials will expand the range of applications and enable the creation of parts with enhanced properties.

- Integration of AI and Machine Learning: The integration of artificial intelligence and machine learning can help to optimize 3D printing processes, improve part quality, and reduce waste.

- Growth of 3D Printing Service Bureaus: The demand for 3D printing service bureaus is expected to increase as more businesses seek to outsource their 3D printing needs.

Conclusion:

Lancashire is rapidly emerging as a hub for 3D printing innovation. The region’s thriving ecosystem of 3D printing service providers, coupled with its strong industrial base and commitment to technological advancement, positions it for continued growth in this exciting field. By addressing the challenges related to material costs, skills gaps, and standardization, Lancashire can solidify its position as a leader in additive manufacturing and unlock the full potential of this transformative technology for the benefit of its businesses and communities. The materialization of innovation in Lancashire is not just a technological advancement; it’s a testament to the region’s enduring spirit of ingenuity and its commitment to shaping the future of manufacturing.